The adhesion of paint or coating to the surface is a crucial parameter to determine its performance and service life. There are a number of external factors such as humidity, temperature, wind, dust, etc. that may directly or indirectly affect the performance of the coatings.

It becomes essential to ensure that the coating doesn’t peel off, especially in industrial applications, which otherwise could cost a ton of money in maintenance, or sometimes could even lead to catastrophes.

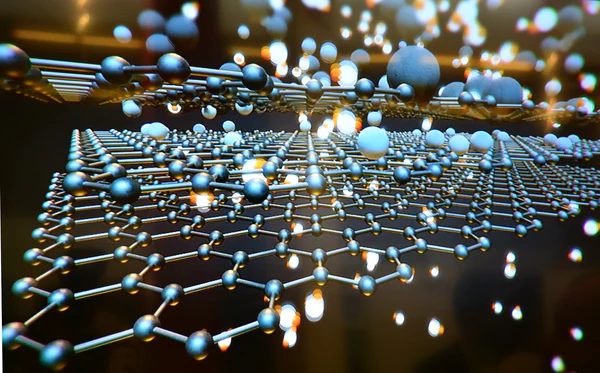

Adhesion promoters play a crucial role in modifying the surface/interface which facilitates the strong bonding on it. They are used as molecular bridges to link organic and inorganic surfaces; and are typically used when there is a substantial mismatch in surface energy between two surfaces intended to be adhered. Commonly used in performance coatings, adhesives and sealants, which are typically used in aerospace, automotive and infrastructure sectors.

They are widely used to make coatings versatile and configure them for use over different types of substrates; for example, adhering plastic to plastic, metal to metal, or plastic to metal. Selection of appropriate promoter depends on the chemistry of the surfaces to be adhered, environmental factors, temperature and desired strength; and determines performance and longevity of the bond.

Additive PMA 700-W is a high-performance organic-inorganic complex compound that is used as a wetting and dispersing agent for waterborne coatings since it offers efficient viscosity reduction in grinding mill base and also enhances color intensity of organic and inorganic pigments. It is also used in water-based ink and pigment paste to increase the tint power of the pigment along with improvement in dispersion & anti-settling properties of pigment and extender.

Additive SC-4 is a specially formulated product developed by creating an organic-inorganic metal complex, a coupling agent between unsaturated polyesters and inorganic fillers or pigments, by forming an atomic functional monolayer over fillers. It significantly impacts the compatibility of organic resins with inorganic fillers which are otherwise less compatible

Additive SC-5 is a coupling agent which acts as a molecular bridge between two dissimilar substrates such as organic-inorganic compounds, such as unsaturated polyesters and inorganic fillers or pigments, by forming atomic functional monolayer over fillers. It reacts at the interface and leads to the formation of organic monomolecular layers on the surface. Inorganics treated by this additive are hydrophobic organophilic and organofunctional which enhances dispersibility, bonding & chemical interaction with the polymer/organic phase.

©2023 PK Enterprise. All rights reserved | Powered by Nyeon Technologies